一、 Discovering Background and Process

- Discovery time: Neodymium iron boron magnets were first discovered in 1982.

- Discoverer: Masato Sagawa, from Sumitomo Special Metals in Japan, was the discoverer of neodymium iron boron magnets.

- Discovery process: During the research process, Zhenren Sagawa successfully synthesized neodymium iron boron magnets with excellent magnetic properties through specific alloy ratios and preparation processes.

二、Development History

1.Initial research:

- After the discovery of neodymium iron boron magnets, scientists began to conduct in-depth research and exploration on them.

- The initial research mainly focused on the chemical composition, crystal structure, and magnetic properties of magnets.

2.Development of Preparation Technology:

- Sumitomo Special Metals has successfully developed the powder metallurgy process for the preparation of neodymium iron boron magnets.

- General Motors developed the melt spinning process, which provided the possibility for the industrial production of neodymium iron boron magnets.

3.Performance improvement and enhancement:

- As research deepens, scientists continuously improve the magnetic properties and stability of magnets by adjusting their chemical composition and preparation processes.

- The emergence of high-performance neodymium iron boron permanent magnet materials has further promoted their applications in various fields.

4.Industrial production and application:

- The industrial production of neodymium iron boron magnets began in the late 1980s to early 1990s.

- With the rapid development of industries such as electric vehicles, energy-saving appliances, drones, and wind turbines, the demand for neodymium iron boron permanent magnets is increasing day by day.

- Neodymium iron boron magnets have been widely used in fields such as electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace, etc. due to their excellent magnetic properties and cost-effectiveness.

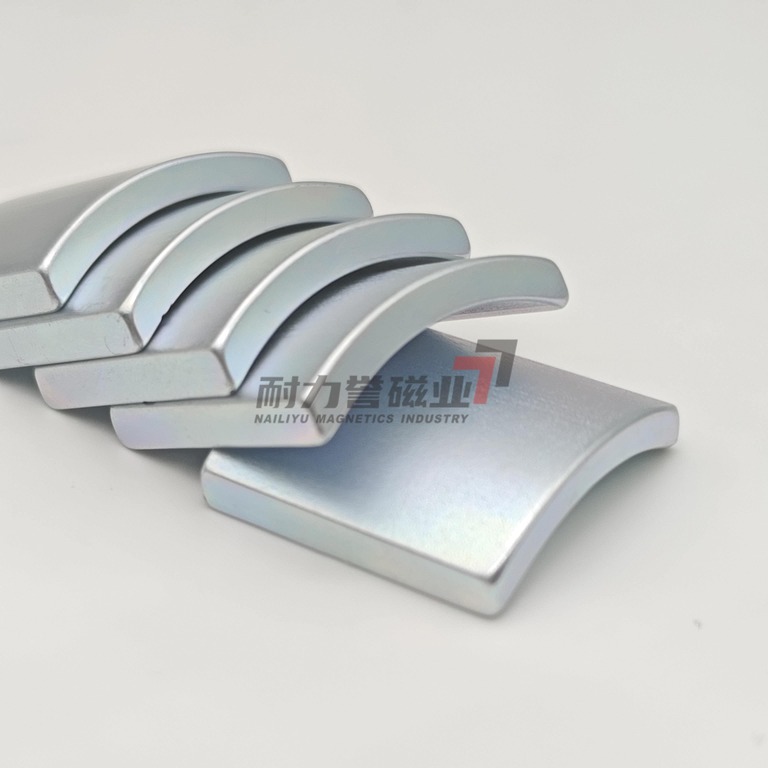

5.Development of surface treatment technology:

- In order to improve the corrosion resistance and service life of neodymium iron boron magnets, scientists have developed various surface treatment techniques.

- Common surface treatment methods include electroplating, phosphating, electrophoresis, vacuum vapor deposition, chemical plating, and organic spraying.

- The development and application of these technologies have further improved the comprehensive performance and reliability of neodymium iron boron magnets.